The LWS31 model is a high performance mechanical seal in technological and hygienic terms. The basis for its design is the LWS30 mechanical seal which is known for its balancing system, making it possible to work comfortably at pressures of up to 35 bar (500 PSI). The rest of the design has been reviewed and optimised with respect to hygienic criteria.

One of the great advantages of the LWS31 seal is its assembly length according to EN12756 (KU) standard, eliminating the need for manufacturers to have to modify the design of their pumps. Nonetheless, in the event of having to adjust this seal to a special size, we can adapt to your needs. Find out more about this model in our catalogue.

LWS31 mechanical seal characteristics:

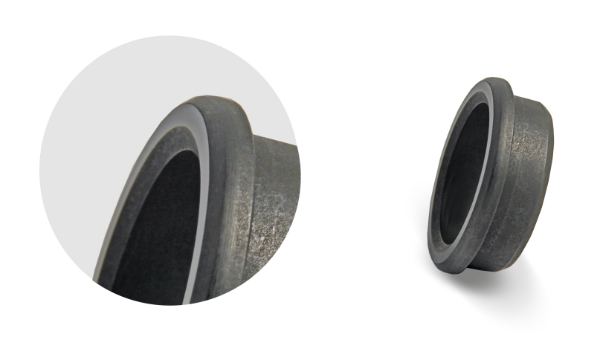

Special finish surface.

All the surfaces of this seal have a special finish that allows them to remain in contact with different types of fluids, thus preventing particles from adhering to the surface and contaminating the next production run. For the same purpose, the edges of the part are rounded, including both the fixed and the rotating part.

Compliant with EU standards.

All the materials used to design the LWS31 mechanical seal comply with the EC1935 / 2004 regulation and directives. In addition, they have been specially selected to withstand different cleaning processes: CIP (Clean In Place) and SIP (Sterilisation In Place). See our certifications.

Absence of shaft fastening screws.

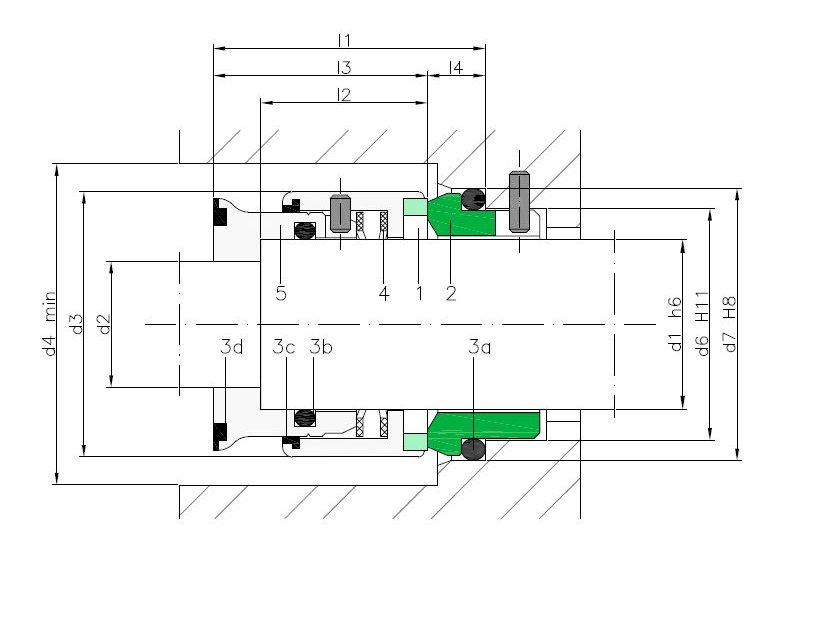

Another feature of this mechanical seal design is the absence of shaft fastening screws to transmit its movement. Holes, threads and screws are potential particle-retention sources and are therefore areas where bacteria can thrive. For this reason, Lidering has eliminated them from this model. The rotation of the rotating part in conjunction with the shaft is achieved by compressing the sleeve (no. 5) that forms part of it.

The rotating part sleeve is mounted on the shaft with diameter d2 while the rest of the part rests on the shaft with diameter d1. The rotating part is compressed by the pump impeller (not shown in the diagram) which rests on the sleeve (no. 5), securing it in place.

The seal sleeve (no. 5) transmits the shaft rotation to the rest of the seal through the anti-rotation pins. The singularity of these pins is based on the fact that they are mounted on the inside in blind holes, thus preventing the depositing of particles and bacteria, as well as preventing leaks.

Wave Spring

The mechanical seal is fitted with a wave spring, which gives this seal its name: LWS. This type of spring allows constant pressure to be applied when it is compressed.

Spring isolation.

The design of the LWS31 mechanical seal isolates the spring thanks to the position of the different seals of the rotating part. This prevents fluids from entering the mechanical seal.

Most of these seals are our own exclusive designs (link to Lidering website). The fact that each component prevents particles from entering the seal or being deposited on its surface improves the behaviour of the LWS31 mechanical seal, extending its life and making it easier to clean.

All the above characteristics make Lidering’s LWS31 mechanical seal the perfect solution for applications that require a high standard of cleanliness and hygiene.