If you want to know all the existing types of mechanical seals and their specifications, you are in the correct place.

In this post, we are going to explain you every type of mechanical seal that we have in Lidering, in order to make easier to you to choose the best one for your application.

We start this express tour for each of the mechanical seals!

Index

How mechanical seals are grouped?

In Lidering we group the mechanical seals in four big groups depending of the type; Multi-spring Seals, Wave spring Seals, Conical spring Seals and Bellow Seals. We are going to explain you their differences and specifications.

Multi-spring mechanical seal

This seals stand out for having different springs inside that make it easier for the force to be distributed very homogeneous between all the faces.

The rotary part has an O-ring that seals with the shaft. If that shaft is deteriorated, could compromise all the sealing system. The rotary part in this seal has three screws that are compressing it. These screws, also transmit the rotation of the shaft to the rotary part, and allow the seal to work regardless of the direction of rotation.

An important feature of the Multi-spring seals is that thanks to the multiple springs, they work well in large shafts as they better distribute the force over the entire contact surface.

Wave spring mechanical seal

In this case, it happens the same as with multi-spring seals, the rotating part has an O-ring inside to seal with the shaft. In addition, they also have screws attached to the shaft, so it is again a mechanical seal independent of the direction of rotation.

Thanks to its specifications, the mechanical wave spring seal behaves well with slightly dirty fluids. Therefore, it is common to see them used in applications that work with wastewater or in systems that work with dense fluids.

This type of mechanical seal usually requires little space but is not recommended for large shaft diameters; this is because the force is not spread so evenly over the contact surface.

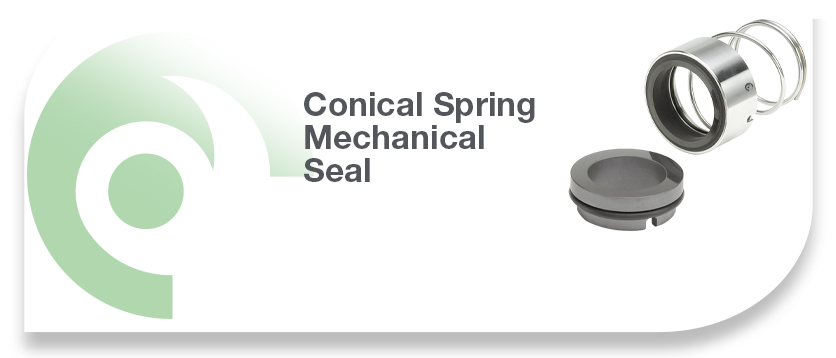

Conical spring mechanical seal

The mechanical seals of conical spring are mainly characterized by its transmission way from the rotation of the shaft to the rotating part; this is achieved by the conical spring.

Thanks to its design, the spring is pressed against the shaft due to the rotation. This system is simple and effective as long as the shaft rotates in the correct direction for which the conical spring was designed, otherwise the effect will be the opposite; the spring will tend to develop resulting in a leak and even causing damage to the components of the seal and the system where it’s mounted.

Mechanical conical spring seals are usually simple and economical to be used in applications without special requirements.

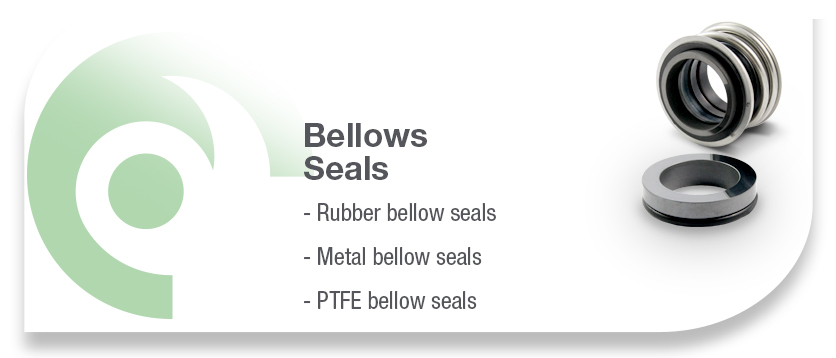

Bellow mechanical seal

There are three types of mechanical bellows seals depending on the material of this component: rubber, metal and PTFE.

Rubber bellow seals

In mechanical rubber bellows seals, this part is responsible for sealing the shaft. Unlike other mechanical seals, rubber bellows tolerates small imperfections and damage of the shaft, as the sealing is carried out on the entire contact surface between the bellows and the shaft and not at a point as in the case of using an O-ring for this purpose.

It is a type of mechanical seal independent of the direction of rotation of the shaft. However, the bellows is not able to keep the seal tight to its mounting height, for this, it requires another element such as a captive ring, a step on the shaft or, more often; the pump’s own impeller.

Like mechanical conical spring seals, they are usually simple and economical.

Metal bellow seals

These are the most efficient seals and made for the most demanding applications.

The metal bellow is the element that provides the force between friction faces. It consists of several sheets welded by a special procedure. It is a design capable of working without blocking with viscous fluids, at high temperatures, chemically aggressive media, cryogenic applications, etc.

They are balanced seals, so they can work under high pressures and withstand vibrations and pressure fluctuations.

PTFE bellow seals

Last but not least, we find Teflon bellows or PTFE mechanical seals. The bellow is responsible of the sealing with the shaft but for this requires an element to keep it pressed against it, a steel clamp. This feature makes the direction of rotation not a problem.

Not having any metal element in contact with the medium is a perfect model for aggressive chemical applications while maintaining the external assembly.

Below, we leave you a link to our contact page if you would like to make any related enquiries. We will be pleased to answer all your questions.