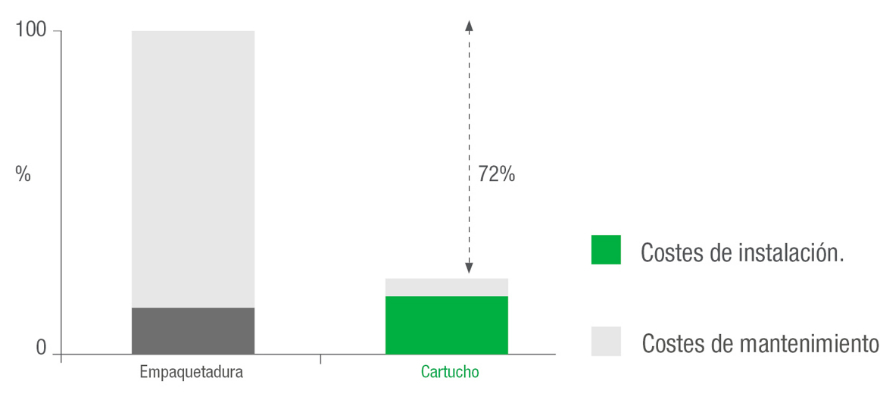

To correctly define the cost of maintaining a system, it is necessary to consider all the relevant issues, in order to make the best decision about which elements to use and how. When sealing a pump, this exercise is even more complex compared to other systems.

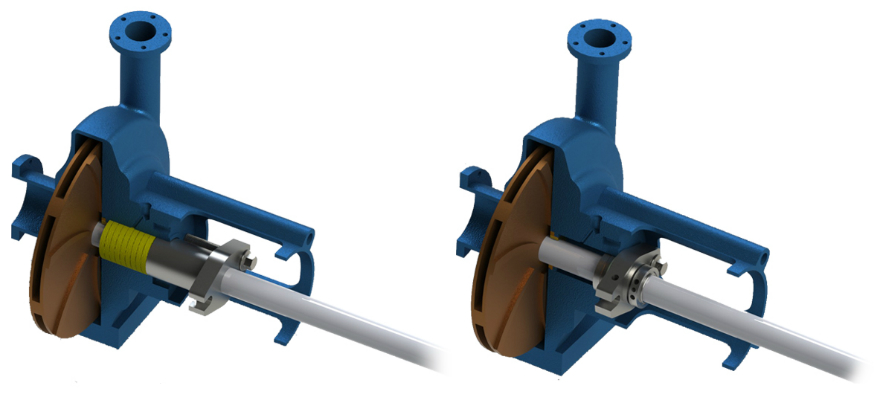

This article explains all the aspects that must be taken into consideration when selecting two of the sealing elements that are mostly used in pump maintenance: braided packing and mechanical seals, especially cartridge seals.

Level of efficacy of a mechanical seal as opposed to braided packing

The first aspect to be considered is the level of efficacy in terms of sealing. In the case of braided packing, total sealing is not possible. The packing system requires the leakage of a small quantity of the pumped fluid to guarantee the lubrication of the packing and prevent its premature wear. This lubrication reduces the working temperature of the packing and prevents it from drying, cracking or burning and being destroyed, which would increase the leakage. Using a mechanical seal ensures total sealing, as the lubrication of the internal components takes place during normal operation, when the seal components are completely submerged in the product.

These leakages required by the packing may become an important problem, depending on the type of product being pumped. If the product is difficult to remove or clean (oil, for instance), this incurs extra costs in system operation and waste treatment. In the case of leakages of dangerous or aggressive products, environmental accidents and personal injuries may result.

Maintenance of mechanical seals compared to braided packing

Another aspect to be considered is the maintenance of the sealing system itself. In the case of packing, its normal operation causes wear which must be compensated by checking and tightening the press screws to ensure the leakage is within acceptable values. On the contrary, a cartridge seal requires no maintenance and, once mounted, it will continue to work as it did the first day until its replacement.

Repercussions of using a mechanical seal as opposed to braided packing

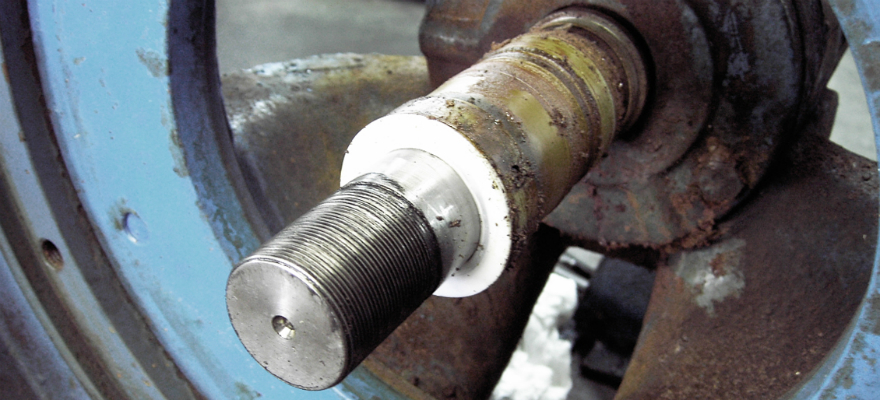

The most important aspect to consider is the repercussion of using packing on the other system components, as the packing works by provoking continuous contact with other pump components, such as the shaft. This gives rise to wear in both the packing and the shaft, making inspection and maintenance operations necessary. Even if the packing is changed, it is often necessary to also have to replace the shaft, leading to a considerable increase in maintenance costs.

On the other hand, when using a cartridge seals, the operation causes contact between the wear components of the cartridge seal which are manufactured specifically to work and support that contact, and so its operation does not affect any other system.

Replacing a mechanical seal as opposed to braided packing

Replacement of the sealing system must also be taken into account, since the time and complexity of the process incur additional costs. In the event of having to replace packing, the press must be dismantled and inspected, and the remains of the damaged packing must be removed from the housing. This may be complex and tedious. Then the new packing rings are cut, which must be carried out with precision, and then inserted in the pump. Lastly the pump is turned on to allow the massive leakage of fluid and the press is tightened until an acceptable leakage level is reached. When a mechanical seal is installed, all that is necessary is to remove the old seal and install the new one.

Possibility of repairing mechanical seals as opposed to braided packing

Another advantage of mechanical or cartridge seals is that they can be repaired, which allows their useful life to be increased and drastically reduces their cost.

Power consumption of mechanical seals compared to braided packing

The aspect that is usually least considered when selecting one sealing system or another is the increased power consumption due to normal operation. In the case of packing, the contact with the shaft acts like a brake, requiring an extra effort by the motor, and this leads to an increase in power consumption. Depending on the characteristics of the system and the application, this consumption may incur an important additional cost.

Testing of mechanical seals compared to braided packing

Lastly, a mechanical or cartridge seal can be factory-tested, guaranteeing its supply to the client in perfect operating conditions. These tests prevent potential failures after being installed, thus increasing customer satisfaction.