In order for a mechanical seal to work correctly, it is essential to guarantee adequate lubrication and refrigeration. In some applications, this is achieved thanks to the use of a secondary fluid, when the primary fluid does not possess the necessary properties.

The provision of this additional fluid involves the inclusion of a secondary circuit, which may be open or closed, and may or may not be under pressure. In the case of opting for an open circuit, the complexity and installation costs are very low, but fluid consumption (usually mains supply water) can become a problem, above all due to current awareness regarding the need to save water.

An alternative to this is the installation of a closed circuit. This avoids wasting the secondary fluid, and in addition allows the use of other fluid types with greater lubricating properties, such as thermal oils, glycols and solvents.

For those cases, Lidering has various solutions, with a full range of auxiliary elements based on the nature of the application:

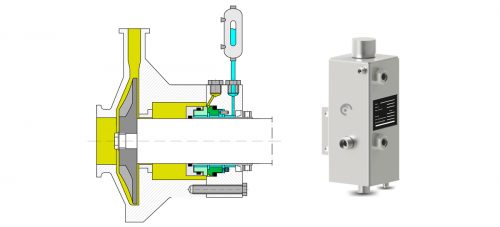

- LQ. This has a 2-litre Stainless Steel tank, which is used for the installation of a Quench or refrigeration circuit. This type of system is mainly used to provide refrigeration for the mechanical seal, and prevent evaporation of the main fluid into the atmosphere. It is also an excellent solution to avoiding dry work during system start-up (flush). In this type of circuit, the secondary fluid is not pressurised. It is used with API 51, 52 and 62 plans.

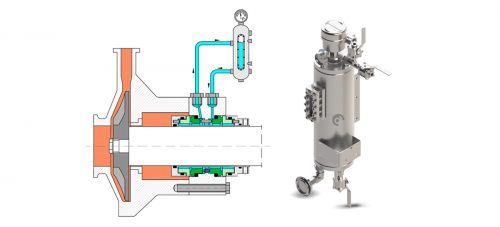

- LST8. This is the basic solution for the installation of pressurised secondary circuits, also known as barrier fluid systems. This type if installation is used to refrigerate, and also to lubricate the seal faces of mechanical seals when the main fluid does not possess adequate lubricating properties. It is achieved by pressurising the secondary fluid to 1.5 bar above that of the primary fluid. This tank has an 8-litre capacity and a maximum operating pressure of 16 bar. In addition, it has an internal coil through which a third refrigeration fluid can flow, in order to thus increase the thermal dissipation capacity of the system. It is used with API 52, 53A, 53B, 53C and 54 plans.

- LST9. This is a high performance tank with a maximum operating pressure of 30 bar and a capacity of 9 litres. It is used in highly demanding applications which are common in the chemical and pharmaceutical industries. They are often fitted to reaction chambers and agitators in order to ensure adequate lubrication and refrigeration of the complex mechanical seals included within systems of this nature. As with its little brother (LST8), this tank includes a peep-hole in order to quickly check the level and status of fluid in the tank, an interior coil in order to achieve greater refrigeration capacity, and various connections for fitting a variety of control instruments, such as manometers, thermometers, electronic level sensors, or even a manual pressurising pump.

Finally, it should be noted that all our tanks can be ATEX certified for Zones 1 and 2.

Do not hesitate to contact us for any further information.