Cartridge mechanicals have long time being a right option in several sectors and applications. Thanks to the benefits they provide, including their versatility, they become essential elements in the pumping systems.

At Lidering, as a sealing solution manufacturer, we have some models of cartridge mechanical seals. Two of them are very important in our catalog; the simple model LSC40 and the double one LDC40.

You may wonder what the differences are between a simple and a double Cartridge mechanical seal.

In this article we want to explain what they are, which differences are between them, what the criteria selection will be and many more features about the Cartridge mechanical seals.

Index

What is a cartridge mechanical seal?

A cartridge is a kind of mechanical seal that lies in a sealing system which is preassembled with components that ease and reduce the possibilities of error during the installation.

This component is preset, that is to say, it is not need to make any additional calculation to decide where to install the seal. Installation is accomplished through the use of “adjusting keys” which are removed after the seal is installed and the pump is assembled. Therefore, the installation is much easier and do not require a specialist to do it.

Among the advantages we can find:

- Simplicity in the installation and repair.

- Greater security while working because its preset reduces any measuring or installing mistake.

- Prevention of any entry of dirt on the contact faces.

- Installation cost is less because installation time is less too.

Within these seals we find the single and the double models that will be explained next.

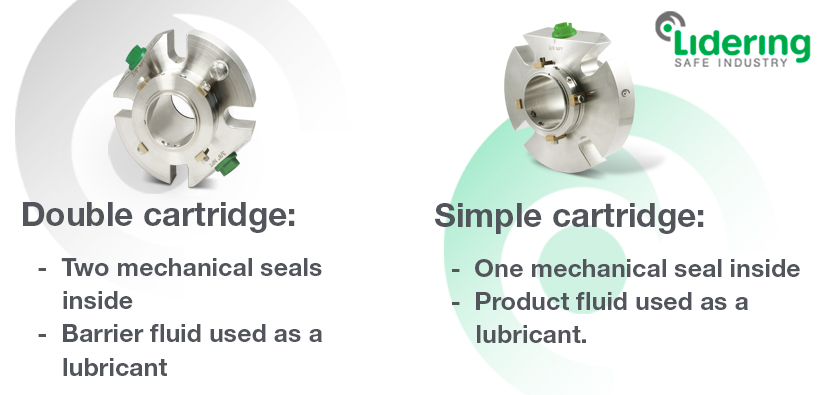

Differences between a single and a double cartridge mechanical seal

Absence of any fluid would make the seal to run dry and heat caused by friction would end up completely damaging the mechanical seal. (Dry Seals)

Mechanical seals use to leak steam from the high pressure side to the low one. The fluid lubricates the contact faces and absorbs the heat generated by the friction that runs across the faces in a liquid form and vaporizes out in the atmosphere.

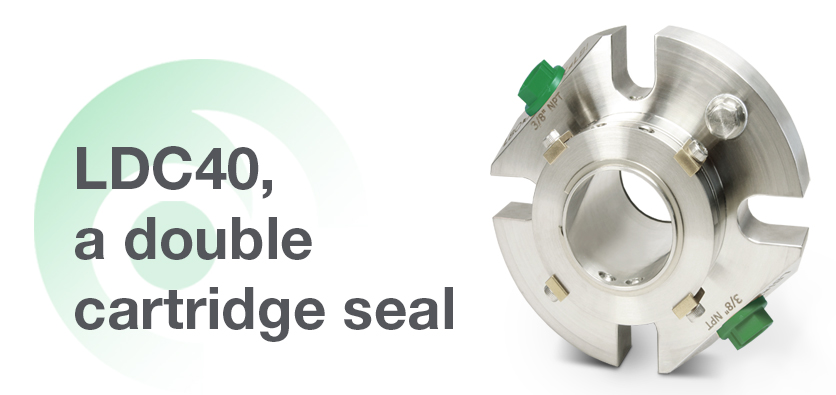

In contrast, a double cartridge mechanical seal is composed by two mechanical seals installed in series. The inner seal, called “primary seal”, keeps the product retained within the chamber of the pump. The outer seal, called “secondary seal”, avoids the barrier fluid to leak out to the atmosphere.

Double mechanical seals are offered in different forms, providing an additional protection. Most usual is “back-to back” form, in which a couple of rotating face parts is installed in opposite directions. Barrier fluid, almost always pressurized, works as a lubricant between them.

To sum up the differences:

- A simple seal has two contact faces while double seals have four.

- A double seal splits in rotary and stationary faces.

- Simple seals use pump fluid as a lubricant while double ones have a secondary fluid (barrier) for this purpose.

Lidering simple and double models

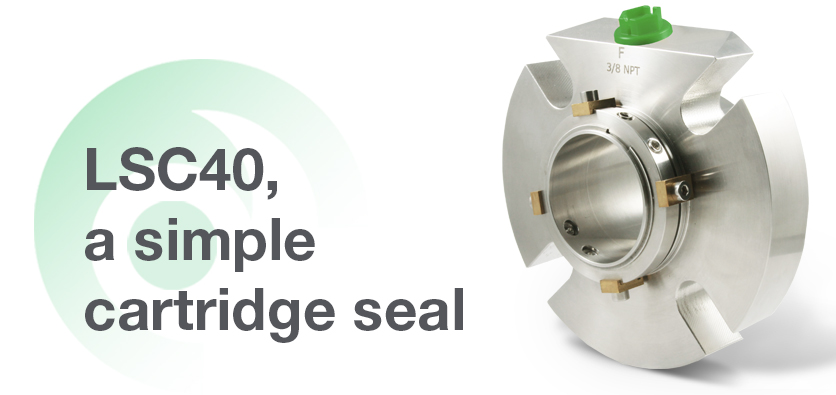

LSC40 model is a simple cartridge seal, hydraulically balanced and including a Flush connection. This allows the recirculation of the fluid across the chamber in which the mechanical seal of the pump is working.

On the other hand, LDC40 model is a double cartridge seal, hydraulically balanced, with an integrated secondary fluid pump system (barrier fluid), that permits the increase of this fluid trough it.

Characteristics of the seals allow them to work up to 25 bar pressure, 16 m/s linear speed and temperatures up to 250ºC if the installed gaskets accord to every specific application.

How to choose the appropriated cartridge mechanical seal?

It is important to know the properties of every system to ensure the best choice for each application.

The most important characteristic to have into account is the lubricating capacity of the fluid to be sealed.

If the fluid to be sealed has lubricating properties, the best solution is the LSC40 simple cartridge. If the fluid is clean or has any particle, we will choose one or another material for the faces. We can also choose an appropriate material for the rubber gaskets having into account the chemical properties of a fluid.

If the product fluid has no lubricating properties, as sticky powder products or gases can be, a double cartridge is the needed solution. This allows to use a secondary fluid called barrier that has the needed lubricating properties to ensure an appropriate performance of the seal.

The barrier fluid must be pressurized in between 1 or 2 more bar than product fluid pressure actually has to ensure an effective lubrication of the mechanical seal. To ensure this pressurization you can choose one of our tanks like LST9 thermosyphon tank.

We hope that this article has been of your interest. If you need more related information, please contact with our department of specialists.