Grinding mills for paints or pigments require special sealing systems, as these products are extremely abrasive.

The grinding mills can be either vertical or horizontal. The grinding takes place in a closed chamber in which very hard pellets of various oxides, glass and silicates, among others, are added, which are agitated via an axle with “fingers” where the pellets collide and the required texture is achieved.

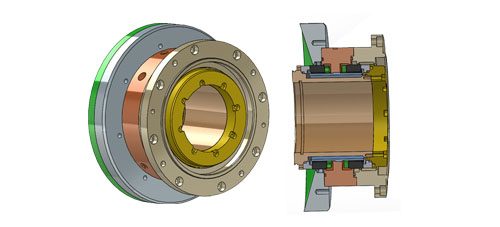

These mills, both vertical and horizontal, have a pump with a mechanical seal which pumps the paint.

This technology is used for the production of high-quality paints and varnishes. This mill grinds paint pigments, printing inks and textile colours, in addition to a variety of solvent or water-based varnishes.

Lidering has become a specialist in mechanical seal solutions for paint mills, for both manufacture and repair.

Ask about our solutions!