Agitators are of the most common industrial systems. They can be used in practically any sector, with the chemical and food industries being those in which this type of machinery is used most.

There are many agitator/mixer designs with a greater or lesser degree of complexity, but they all have a common basic concept; they are used in tanks or similar devices into which different substances are poured and stirred using a rotating paddle system to mix them. Reactions usually occur between the added products, and for this reason these mixtures/reactions must remain under controlled pressure and/or temperature conditions.

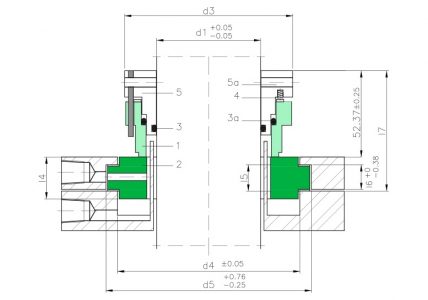

Again, we have a pressurised system with a rotating element that requires a mechanical seal. In such cases, one of the simplest options with the greatest benefits proposed by Lidering is the LMS28 model.

This seal is a balanced seal specially designed to work at counter pressure in vertical agitators. The above characteristics also enables it to work at high pressures up to 15 bar.

In applications of this type, the product is usually at the bottom and so the seal works under dry conditions, with no lubricant. To prevent this condition from affecting the seal, the part in contact with the rotating part is made of specially-designed graphite.

A large, solid graphite body that can operate under dry conditions at linear speeds of up to 2 m/s and dissipate the temperature that is generated.

This seal may also incorporate a DEBRIS system. This system is useful in applications that require a very high level of protection from product contamination.

It consists of a special flange that prevents tiny particles produced by normal seal wear from falling inside the agitator and being mixed with the product. It also has two connections to permit the washing of the particles that have accumulated inside the flange.