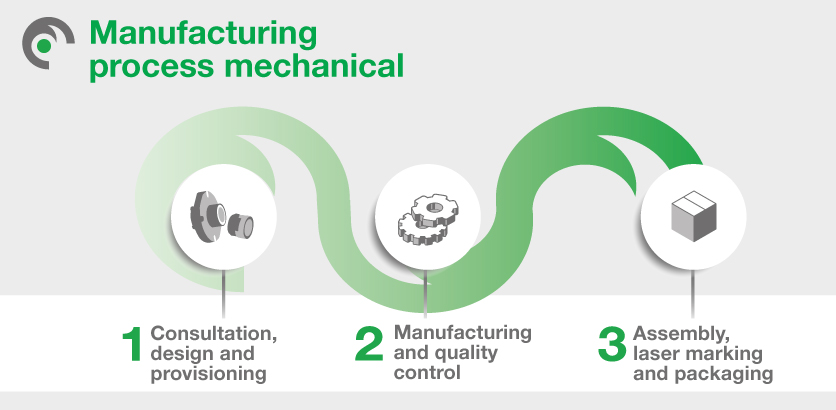

Did you know that the manufacturing process of a mechanical seal goes through different stages?

The manufacturing process we carry out in Lidering is carefully analyzed to optimize our resources and give an excellent service to our customers.

The experience and the years that guarantee us, has made us follow a different workflow according to the needs that have been happening, until arriving at a working system, optimal and efficient.

The group of experts in mechanical seals and associated products for the industry, added to our ability to adapt to the requirements of our customers, is a combination that forges what we are: a reliable partner.

Do you want to know more details about the internal procedures we do in Lidering?

Keep reading this article and find it out.

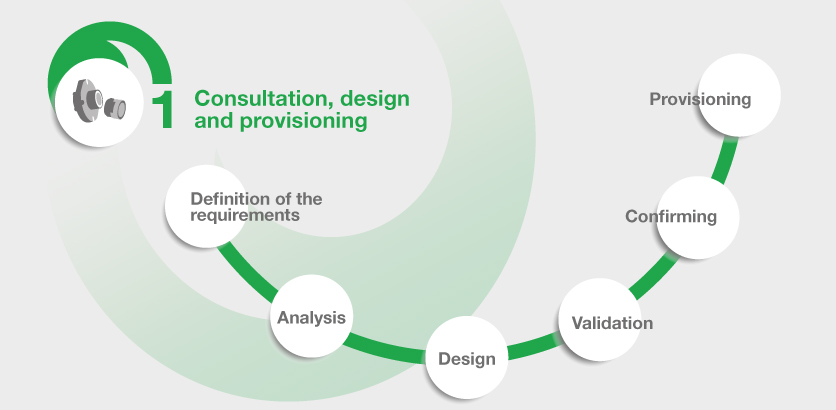

Phase 1 of the mechanical seal process: Consultation, design and provisioning

A: Definition of the requirements

It all starts with a customer consultation to our sales department.

The consultation is managed with maximum agility to provide a response as fast as possible and so the user knows at all times what is the situation of their demand.

B: Analysis

From this point, the consultation is transferred from the commercial department to the engineering department, where an engineer specialized in mechanical seals analyzes in detail the customer’s needs.

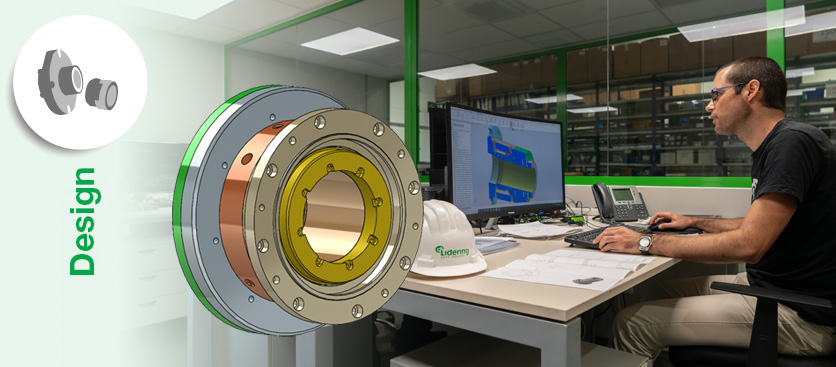

C: Design

Engineers, applying their knowledge in the field, create a prototype design from 3D modeling programs such as Solidworks or AutoCAD.

D: Validation

Subsequently, the prototype designed, is sent to the customer so he can verify that the proposed solution meets the expectations demanded and adapts to the requirements of the application.

E: Confirmation

If the customer finally accepts the prototype, the commercial department reflects in our ERP (Enterprise Resource Planning) the production order.

F: Provisioning

With this planned production order, the purchasing department can start supplying all the raw material for the mechanical seal manufacturing process.

The supply chain is a fundamental part of the process, because a poor management can lead to stock breaks or delays in the future phases of the procedure, especially in this era in which we suffer a major crisis of raw materials and logistics.

G: Production planning

Depending on the load in the supply chain, the production manager manages the delivery times.

Meanwhile, the engineers of the technical office determine the production procedures.

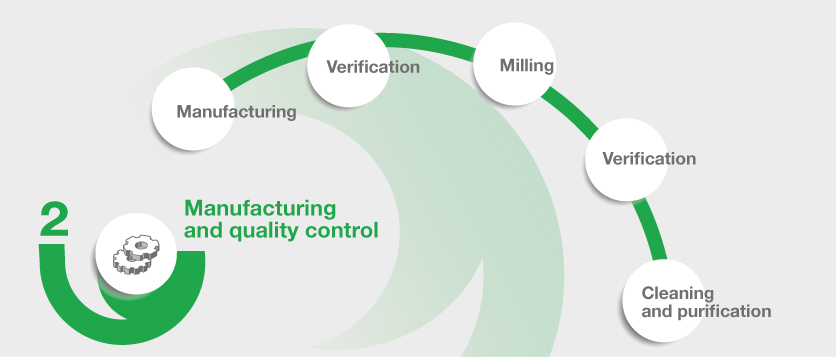

Phase 2 of the mechanical seal process: Manufacturing and quality control

A: Manufacturing

The second phase of the mechanical seal process focuses on manufacturing. The manufacture is made on conventional machines or CNC automatic machines.

The manufacture team prepares the right tools for handling each raw material and then they can start manufacturing.

B: Quality control

Once the first parts are finished, the same lathe operator performs a quality control to ensure the correct condition of the manufactured parts.

C: Milling

Then operator performs the next step in conventional milling or CNC machines.

D: Cleaning and purification

Once the milling process is finished, the same operator polishes the parts by removing the burrs with small pneumatic machines while the CNC machine continues the other series.

In this process, not only the burrs are removed from manufactured parts, there is also cleaning process by removing any remaining impurities and dirt.

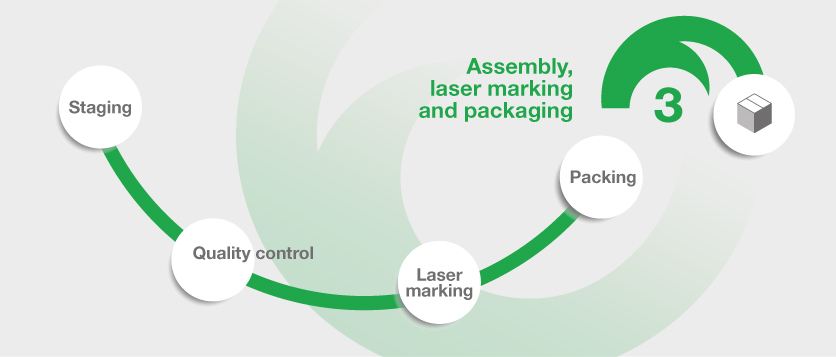

Phase 3 of the mechanical seal process: Assembly, quality control, laser marking and packaging

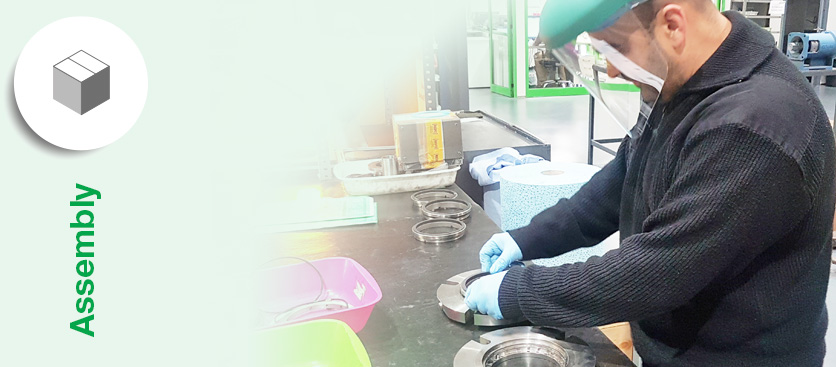

A: Assembly

With the components ready, the operator begins the assembly of the mechanical seal taking into account the appropriate adjustments and the correct manufacture of the parts that comprise it.

B: Leak test

After assembly, a static seal test is always performed on all mechanical seals. This ensures that the mechanical seal does not leak.

C: Laser marking

The next mechanical closing process consists of laser marking with our precision machines. This marking task performed by the logistics operator allows to reflect our logo and, if necessary, the ports of connection.

D: Packaging

Finally, the mechanical seal is packaged to obtain the greatest possible protection to ensure that the contents are not damaged during transport.

Roles of the mechanical seal process

Before finishing, we want to review which roles of the mechanical seal process are involved and in which phases they have participated:

- Commercial (Phase 1)

- Technical engineer (Phase 1)

- Buyer (Phase 1)

- Production manager (Phase 1)

- Lathe Operator (Phase 2)

- Milling Operator (Phase 2)

- Logistics Operator (Phase 3)

With this article we hope you have been able to discover the phases of the manufacturing process and design of a mechanical seal.

Below, we leave you a link to our contact page if you would like to make any related enquiries.

Contact our professional team so they can advise you.