When a process implies working with chemically very aggressive fluids, our systems’ components must be prepared for it, including mechanical seals, thus avoiding their becoming of the weak link in the installation.

Acid and alkaline solutions in very high concentrations are common both in the chemical and food industries. In the automotive sector, for example, decanting pumps of acids, such as hydrochloric and sulphuric, can be found as mordants to strip metal plates destined to bodywork. In the paper industrya multitude of alkaline, such as sodium hydroxide, and acid substances, like chlorine dioxide and hydrogen peroxide, are used to obtain and whiten cellulose. In the food industry it is frequent to use substances such as phosphoric acid to manufacture a variety of products.

Standard mechanical seals in contact with such aggressive chemical products are chemically attacked. The model LTB16 is the solution, both for its design and for the quality of its construction materials.

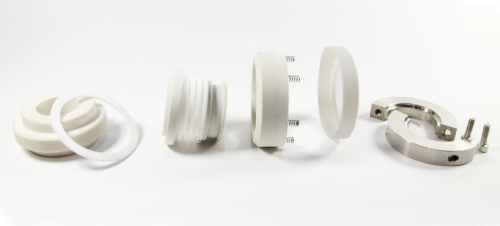

The stationary friction surface of this Type T model is made of Alumina (aluminium oxide) with a purity of 99%. This material is one of the most chemically resistant materials that exist in nature, it is considered inert for a range of ‘normal’ temperatures and it is practically impossible for it to react in contact with another substance. It also shows high resistance to wear, since it is one of the toughest substances there is.

On the other side, the friction surface on the rotating part is made of PTFE, one of the synthetic materials with highest chemical resistance. Besides, it shows self-lubricating properties that reduce wearin conditions of scarce lubrication

As secondary joints, it uses two flat joints of PTFE for the stationary part and a PTFE bellows for the rotating part. With these designs and materials we manage to ensure that the sealing points will not be chemically weak. Moreover, the fact that the rotating friction surface is made from the same piece of PTFE as the bellows, reduces the possibility of there being any leak.

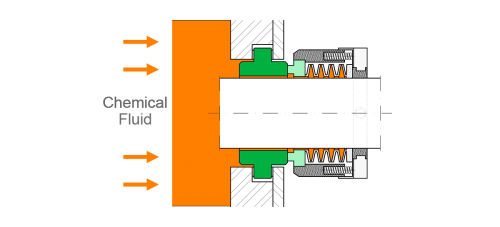

The internal design is another differentiating aspect of the LTB16. The fact that the PTFE bellows is balanced and that the stationary part has the shape of a T allow the seal to be installed externally, avoiding that the fluid comes in contact with the internal parts of the seal(springs, exterior casing or flange).

This characteristic, along with the self-lubricating capacity of the PTFE surface, enables the LTB16 seal to be used in vertical agitators, in which rotation velocity is not very high.

The fact that the LBT16 is balanced also permits it to be used in vacuum conditions.

For all of these reasons, the LTB16 is an ideal seal for a variety of chemically very aggressive applications.