To manufacture the paper used in high-quality prints like magazines, catalogs, etc., a special treatment called stucco is required. This process consists of adding one or more layers, based on the quality, of a special mixture of Calcium Carbide (70%), Latex (20-30%) and other substances like starch and NaOH, to the finished paper.

This mixture is transformed into a viscous and adhesive substance that must be applied in very specific concentrations and dry in short spans of time, so that the paper does not stick when winded and forms a solid cylinder of unusable material.

The properties of this substance, added to the specific needs of its application, make the stucco a critical process in the paper sector.

In order to pump such a viscous and adhesive substance, PCP pumps with positive displacement are necessary. These are capable of working with high density fluids.

Another complex point is choosing the adequate sealing system, the characteristics of the fluid and the requirements of the application, which make impossible the use of recirculation elements like ‘Flush’, given that if the product fluid is used for the recirculation, it would solidify and block the conducts. Moreover, the use of any external fluids that might mix with the product fluid is rejected as well, because its concentration might be modified and the production damaged.

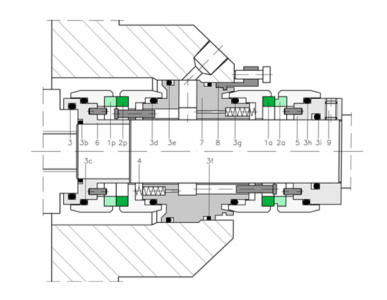

Lidering offers a specific solution for this critical process. It is a special design inspired by our double standard cartridge, the LDC40, a version which assembles one of our metal bellows seals, the LMB85, in order to work on the product side. The use of a metal bellows seal is ideal for working with high density fluids. When turning, it exerts a propulsion effect that stirs the fluid in the chamber of the mechanical seal, making it more difficult for the fluid to solidify and block the seal.

On the atmospheric side, we maintained the same design as the original LDC40, with its characteristic elements such as the barrier fluid pumping ring and the purge systems.