Rotary seals are systems that are used to seal unions between fixed and rotating elements.

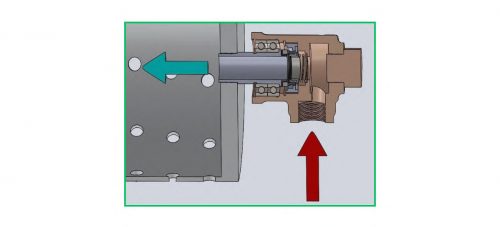

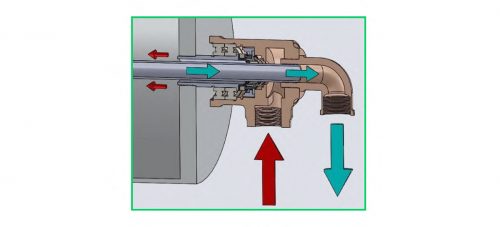

They basically consist of a connection guide element, a graphite bearing or bushing and a mechanical seal to seal the union.

There are rotary seals for water, steam, oil and many other applications.

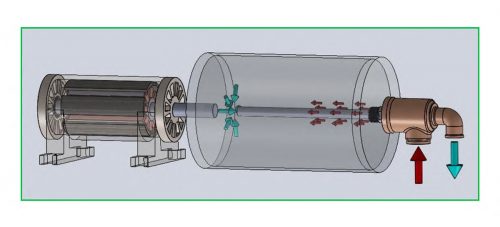

They usually function by letting the fluid to be sealed pass through the rotary connection, which is known as a one-way rotary seal. There are also seals that permit the fluids to pass through in both directions, without the incoming fluid being mixed with the outgoing fluid. This type of seal is called a two-way seal.

There are models with the ability to seal various pipes at once, enabling different fluids to be channelled to different systems without being mixed. This type of rotary seal is known as a multi-way seal. Consult our catalogue at the following link: https://www.lidering.com/en/products/

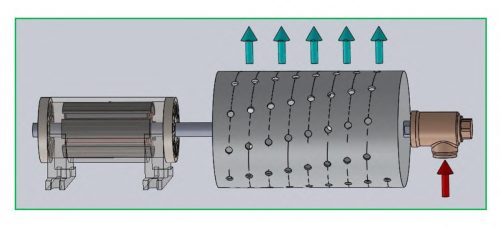

Rotary seals can be found in practically any industrial sector, but they are very common in industries in which flattening or drying drums and calendars are needed, such as the textile or paper industries.

However, they may also be used in other sectors such as iron & steel and glass, where cooling calendars are common, in wind turbines or in CNC machining centres. In other sectors as varied as the building and mining sectors, rotary seals are also used in lubricated heads. For instance, they are used in automated milking machines in the dairy industry.

In addition, they are frequently used in stamping presses, one of the machines most commonly used in different industrial sectors.

Consult our catalogue at the following link: https://www.lidering.com/en/products/