The Productive Centre in Reus has been Saqr-ATEX certified. This certification allows us to carry out repairs on non electrical equipment with ATEX certification of any type and category: mechanical seals, cartridges, pumps, agitators, etc.; Area 0, 1, 2, 20, 21, 22, etc.; while maintaining the same level of ATEX certification.

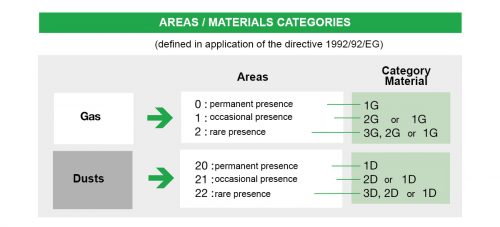

As a reminder, the ATEX certification is applied to those devices that work, or can at any time find themselves working, in potentially explosive atmospheres. The ATEX normative classifies these situations using Areas, thus we have: Area 0 for applications in which the presence of an explosive atmosphere is permanent; Area 1 when this explosive atmosphere only appears occasionally; and Area 2 for those applications where an explosive atmosphere is rarely presented.

In order for equipment with ATEX certification to maintain the same level of original protection once repaired, a series of procedures need to be carried out and specific material must be used according to what is indicated in the Saqr-ATEX referential version 8.0.

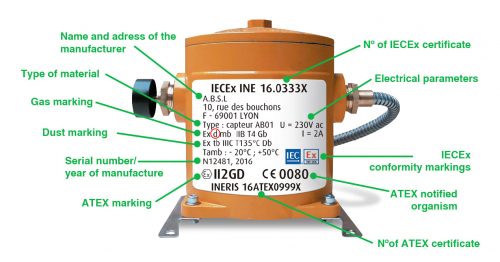

How do we know what level of protection the equipment has?

This can be observed in an indicative plate that accompanies the equipment, in which the classification is specified through a letter code. In the following picture we can see an example:

In the gas marking the letter ‘d’ indicates ‘antideflagrant covering’, a system that consist in confining the components that might catch fire in a chamber (covering) that can resist the rise in pressure produced by the deflagration, avoiding contact with the exterior environment. These types of structures must be repaired strictly respecting the interstice between the surfaces that close the chamber, the characteristics and dimensions of the joints and the volume of the chamber.

In this case, and so that these requirement can be met, our personnel, who are qualified specifically for this type of Saqr-ATEX repairs, will initiate the repair according to these indications and following a specific protocol that avoids the wear of the components of this equipment, guaranteeing at the same time the traceability of their interventions. All of these operations will be accompanied by demanding dimensional controls, in order to finally carry out definitive tests that will confirm and certify that the equipment can be used again with absolute guarantee and safety.