In the article posted today, we are going to pay special attention to one of the essential element of mechanical seals: the spring. This compound is responsible of many aspects extremely important for the right performance of the seal and, by extension, must be the object of attention and evaluation.

Specific coating treatments are one of the main points to maintain a good state of the spring and, by extension, to extend the service life of the mechanical seal. There is a large variety of industrial treatments for springs of mechanical seals so choosing the appropriate solution is a matter of extreme importance. We can help you here.

What a spring in a mechanical seal is used for?

The spring is used to keep the faces of a mechanical seal together when is the fluid pressure in the chamber is low. It also absorbs and compensates vibrations and movements in the equipment as well as to balance the possible wear of the contact faces.

In addition to its working importance, the spring is one of the most critical parts of a mechanical seal. It can easily rust being one of the “weakest points” as it is susceptible to wear or being damaged in the first place.

Spring corrosion according to mechanical seal mounting methods

In a double mounting, springs may contact the barrier fluid. It protects the spring of a direct exposure to aggressive and corrosive fluids. However, in simple mountings, springs are in contact with the process and are very susceptible to damage.

There are other solutions like the external mounts. In this case, the spring is found in the stationary part and it is not in touch with the aggressive product fluid. However, a possible natural evaporation of the fluid might be considered here resulting from the normal working of the mechanical seal. And it could corrode the spring

Surface treatment to avoid the corrosion of springs in mechanical seals

For all of the above reasons, Lidering strongly recommends to pay special attention to the treatment of the springs of the mechanical seal.

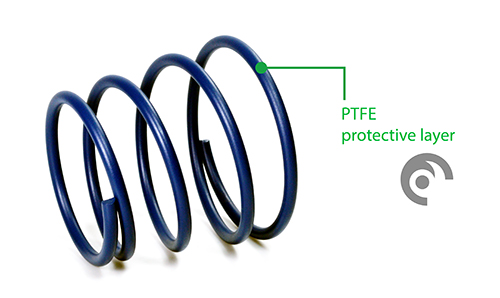

An easy solution to those problems may be the coating of the spring through treatments that involve the application of a protective layer made of PTFE (Teflon®). This would provide an exceptional chemical resistance to the spring, increasing its service life and, consequently, the mechanical seal one.

There are several spring surface treatments with different thicknesses, mixtures and colors. The choice would depend on some features such as the working environment, the intervening product fluids or the attribute of the manufacture. Our team of experts in sealing would help in finding the most accurate solution for every application.