Water is the most important fluid for life, and there is no living being that can survive without it. However, water treatment is also essential for the industry as a whole. From cooling systems to hydroelectric generation processes, concentrators, evaporators, reactors, etc., all of them require water (in its various states) to perform their function correctly.

In Lidering, we discuss the water treatment process and how to optimize the use of water resources, which require specific solutions to ensure water efficiency.

Industrial challenges using water as the primary fluid

There are many industrial sectors dedicated to water treatment in order to use it as the primary fluid, and some can acquire significant importance in the economy. Among all types of industries related to water, perhaps the most important ones are hydroelectric power plants, wastewater treatment plants, desalination plants, or pumping stations.

What do these industries that work with water have in common? Industries that work with water as their primary fluid face unique challenges, particularly due to the high pressure of their equipment. From turbo-pumps in pumping stations to those used in desalination plants, specialized solutions are required to maintain optimal performance. In the first case, water treatment involves supplying large flows at high pressures; in the case of desalination plants, water needs to work at high pressure to carry out osmosis processes.

Specialized solutions in water treatment

In industrial sectors requiring water and other fluid treatments, the LSC10B-FQ model stands out as an ideal solution for high-pressure and high-speed industrial applications.

How does the LSC10-BFQ mechanical seal work? This mechanical seal is capable of withstanding high-pressure work, thanks to its balanced multi-spring seal. Both the materials and the design have been chosen to operate at high pressures and/or rotational speeds, due to their balanced and specially reinforced rubbing faces, the special Quench system, and the Flush connection.

Promoting water conservation in industry: API Plans

Just as it is desirable to use a type of mechanical seal for the water treatment industry, it is also important to explore different types of assemblies and alternatives that promote water conservation.

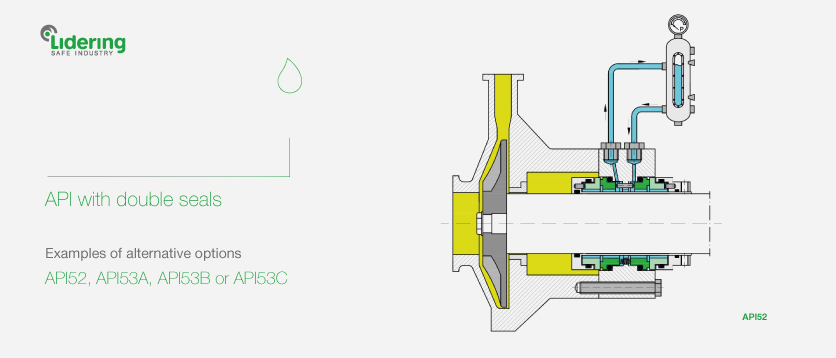

The different API plans types offer effective strategies for reducing water consumption, such as API31 plan and double seals according to API52, API53A, API53B, or API53C plans.

When working with dirty fluids, the API31 Plan should be used, where a cyclonic filter is interposed between the pump discharge and the injection into the seal chamber. In API32 Plan, pressurized fluid is supplied to the seal chamber from an external source. This allows us to use the same fluid we are pumping to renew the fluid in the sealing chamber and extend the life of the mechanical seal without the need for additional water consumption.

Another option is to use API PLANS with double seals, which protect the seal by circulating fluid through a closed circuit. Some examples of these setups are API52, API53A, API53B or API53C plans.

Likewise, the same assembly concept can also be applied to API plans for seals with Quech. API62 Plan uses an external fluid source for cooling the seal. This could also be achieved using API51 Plan where, again, a reservoir is used for cooling the seal through a closed circuit.

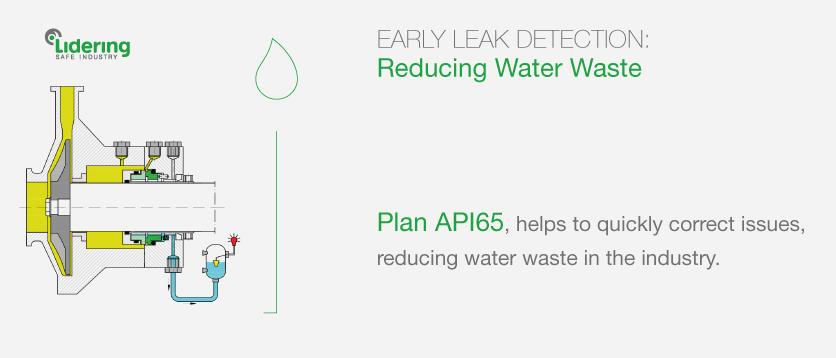

Early leak detection: reducing water waste

Finally, it is important to mention the various leak detection measures that allow correcting the problem as quickly as possible, thus reducing the amount of water wasted in the industry.

An example is the implementation of API65 Plan, where the seal has a “Drain” connection where a sensor can be connected to detect the leak and alert of seal failure, or even automatically stop the system.

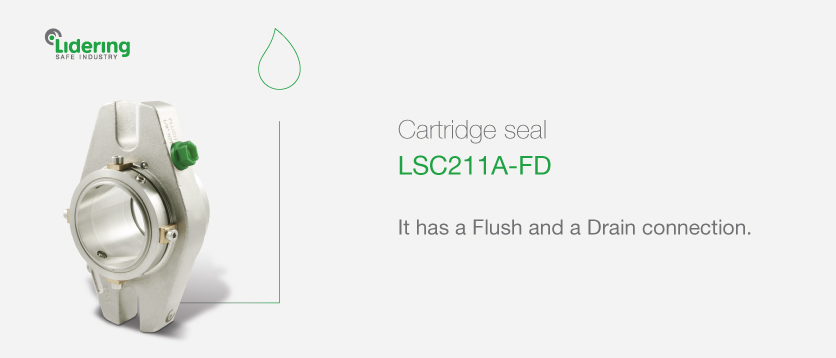

Do you need a mechanical seal for water treatment? At Lidering we have the LSC211A-FD cartridge seal, which features both a Flush and a DRAIN connection.

Contact Lidering and together we will figure out how to provide you with the best mechanical seal solutions for effective water treatment, essential for the environmental sustainability and operational success of your industry.